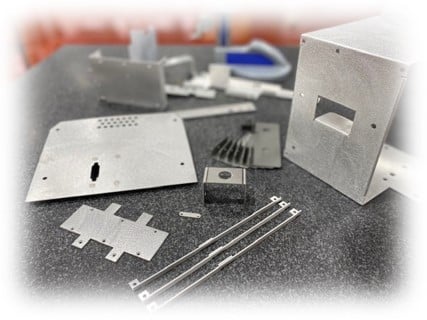

At GTR Manufacturing, our role as a precision sheet metal fabricator goes far beyond simply producing high-quality parts. We are committed partners throughout the entire lifecycle of our customers’ products—from the initial prototype to end-of-life obsolescence.

This full product management approach to sheet metal fabrication is a true differentiator for GTR and is just one more way we put customers first.

Collaboration from Day One

Together, we’ll identify and resolve any challenges related to:

- Cost optimization

- Design for manufacturability

- Product quality

By proactively partnering up front, we aim to ensure a smooth transition from prototype to full production without any delays or unforeseen roadblocks.

Continuous Improvement Mindset

During the prototyping stage, our engineers leverage their deep sheet metal fabrication expertise to provide continuous quality improvement recommendations. At GTR, we obsess over the smallest details that could impact the efficiency and cost of producing your parts in the future–especially when your quantity needs increase.

For example, we recently advised a customer to make a minor change to their part design to remove a small overhang on a foam gasket. While it may have seemed insignificant during their initial 10-piece run, we knew the overhang would create extra labor costs and impact their lead times for higher volume production.

This dedication to optimization from the very start of the sheet metal fabrication process is a hallmark of the GTR experience. We persistently pursue product improvements and aren’t afraid to have tough conversations because we know it will save our customers significant time, money, and difficulties down the road.

A Seamless Transition through All Volumes

Our full lifecycle capabilities truly shine as products transition from prototypes to full production and beyond. With the ability to handle both high- and low-volume sheet metal fabrication orders under one roof, we can support all of your production needs—whether you need 10,000 parts or 10.

By working closely with your team through every phase of production and leveraging our extensive in-house capabilities, we eliminate the headaches and hiccups that can occur when you transition between manufacturing partners—a common issue when part volumes change.

Make GTR Manufacturing Your Ultimate Lifecycle Partner

Not all sheet metal fabrication partners can provide full lifecycle support for their customers’ parts. But at GTR manufacturing, we have your back from the initial prototype through high-volume production and beyond.

This level of comprehensive support is possible thanks to our:

- Robust manufacturing capabilities

- Dedication to continuous improvement

- In-house engineering expertise

- Unwavering commitment to customer satisfaction

While the path from prototyping to obsolescence can be long and complex, you can trust that GTR will be with you every step of the way, providing solutions before challenges even arise.

This level of support is one more way we aim to be a single-source solution for all of your manufacturing needs.

Are you ready to experience the GTR difference for yourself? Get a Quote today!