At GTR Manufacturing, we specialize in the precision sheet metal fabrication of complex enclosures.

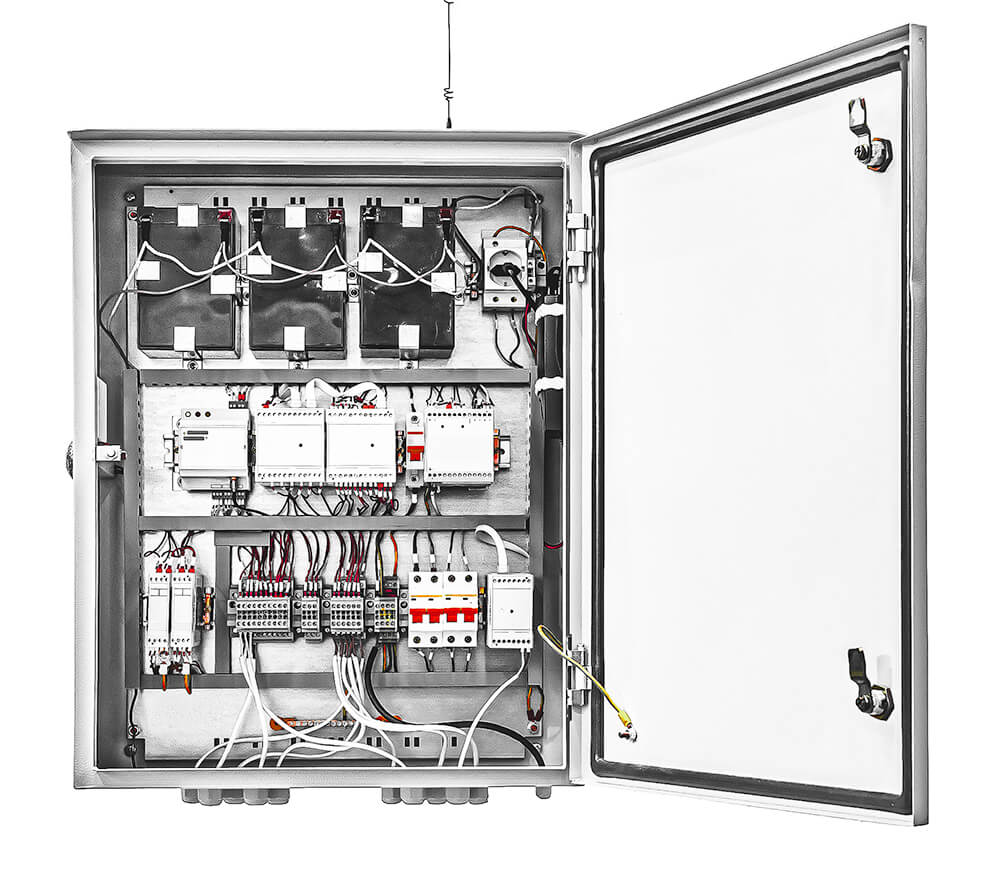

What exactly makes an enclosure complex? Generally speaking, we’re talking about enclosures requiring high precision across multiple integrated subassemblies. Often built for the medical and science industries, these enclosures include components such as circuit boards, monitors, and push buttons.

And on top of all that? Many of these individual components have strict tolerance requirements of their own. These tolerances must be met with high precision to ensure proper fit and function within the final assembled enclosure. Even a slight tolerance miss on a single component can derail the entire project and lead to customer frustrations when the enclosure doesn’t function as intended.

This exact situation recently brought a prospective customer to GTR Manufacturing. The front door of their enclosure has a sensor that detects radiation, and for the sensor to work properly, the door must be completely flat. Heat distortion during the manufacturing process has made it challenging for them to achieve the required flatness.

It’s not that the project isn’t doable; it just requires a precision sheet metal fabrication team with the right expertise to prevent heat-induced distortion.

That’s where we come in.

Why Choose GTR for Complex Enclosures

At GTR Manufacturing, quality is paramount in everything we do—and quality is especially important when dealing with complex enclosures. After all, these enclosures do more than simply hide electronics; they can also help perform life-saving work.

That’s not an overstatement! We’re currently working with a customer in the medical industry to build enclosures used in laboratories for cancer treatments. The cables, harnesses, and integrated components within these enclosures must function flawlessly–patients’ lives literally depend on it. Quality-wise, every step in our manufacturing and assembly process must be carried out precisely.

Here are four ways GTR stands out when it comes to manufacturing complex enclosures.

#1: Over half a century of excellence

We have decades of precision sheet metal fabrication and welding experience under one roof and are committed to training the next generation of professionals. Our apprenticeship program ensures the 50+ years of knowledge we’ve gained in our facility funnels down to our newest employees. Through this process, they learn from the best in the business (instead of by trial and error).

#2: Rigorous inspection processes

A key way we avoid quality issues is through our first-piece inspection process. At GTR, we conduct a first-piece inspection after every operation. All parts and assemblies also undergo a robust final inspection process to promptly identify and address quality issues.

#3: Quality craftsmanship

At GTR Manufacturing, our enclosures are not only functional but also aesthetically pleasing. We take our precision sheet metal fabrication and assembly services to the next level by welding, grinding, and blending the metal components to create an enclosure that looks like a single uniform piece.

It’s a process that requires a great deal of craftsmanship and a commitment by our team members to go the extra mile for customers.

#4: Single-source solution

Not only do we provide a full suite of precision sheet metal fabrication and welding services, but we also offer in-house finishing services such as:

- Brush finishing

- Painting

- Powder coating

- Silk screening

With all these services under one roof, we can handle all aspects of your complex enclosure—from engineering support to finishing. This integrated approach ensures we maintain full control over the quality of your assembly at each stage. It also saves you from the hassle of juggling multiple vendors.

Partner with GTR from the Start

Whether you’re in the design phase or have a complete blueprint ready, involving GTR early in the process can significantly enhance the manufacturability of your enclosure (and lead to cost savings)! Our goal is to create a smooth manufacturing process that is as efficient and straightforward as possible for our customers.

There’s no room for error when manufacturing complex enclosures for critical applications. Trust the GTR team, which has spent decades learning to overcome heat distortion and other common points of failure in these important assemblies.

From initial design collaboration through final assembly, the GTR team will deliver manufacturing solutions that will exceed your expectations.

Ready to get started? Request a quote for precision sheet metal fabrication services today.