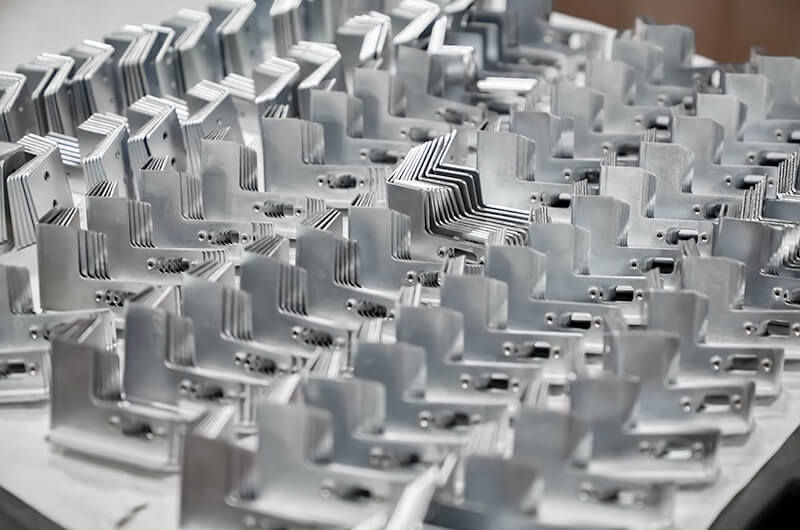

Precision Sheet Metal Fabrication

Sheet Metal Prototyping

Lightning Fast • Superior Craftsmanship • Engineering Expertise

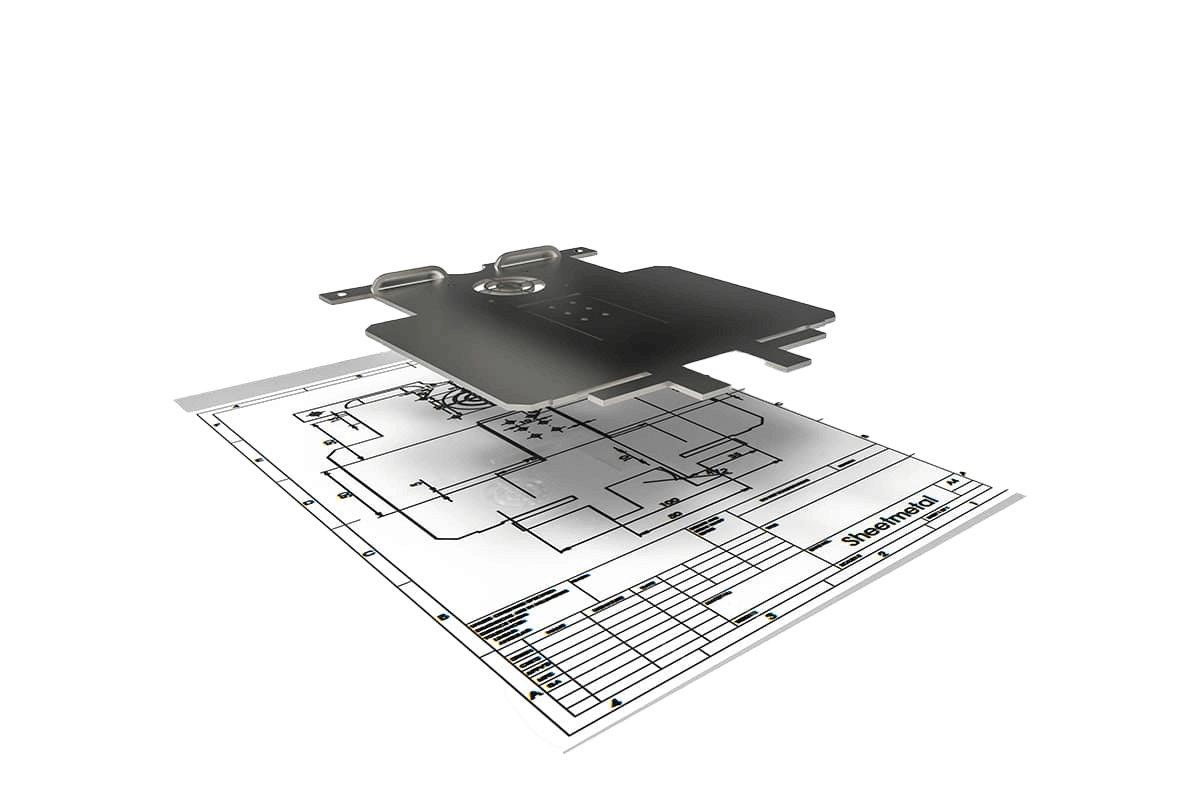

Sheet Metal Prototyping: Fast Track Your Next Great Idea

With over 50 years in the sheet metal prototyping business, we know great ideas cannot wait. Our team of seasoned engineers, expert craftsmen, and state-of-the-art technology enables us to offer sheet metal prototyping at precision quality and lightning speed.

We serve engineers, mechanical designers, NPI buyers, innovators, and entrepreneurs alike. From start-ups to Fortune 500 companies in the medical, robotics, and hi-tech industries, we produce precision sheet metal prototypes in quantities of 50 pieces or less. And as part of our 50+ year commitment to unparalleled customer service, we offer engineering and design support and cost-reduction ideas whether you’re a seasoned engineer or a first-time innovator.

In order to serve a growing market demand for faster turn-around times, higher quality products, and a relentless dedication to the overall customer experience, GTR ProtoPlus was born—our sister company that is laser-focused on low-volume, sheet metal prototypes.

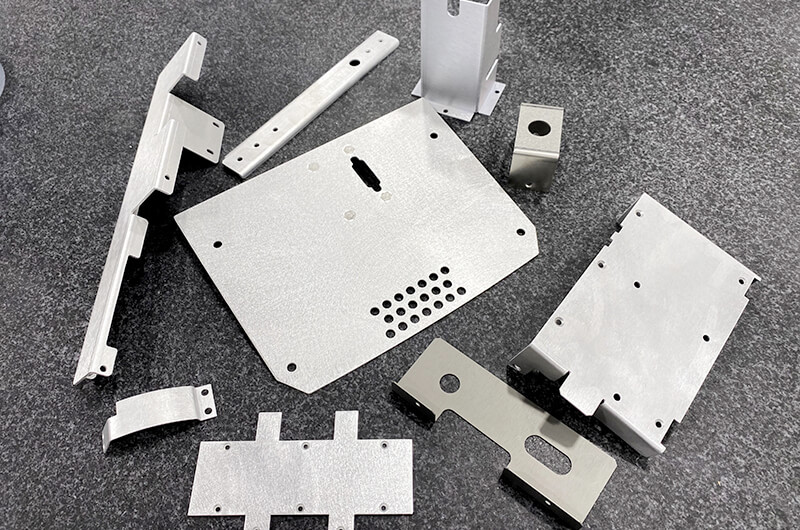

Whether it’s a simple bracket, a complex chassis, or a high-end electromechanical enclosure, we commit to quoting each order in hours and have it designed to spec and on your desk within days.

What’s more, as a large-scale precision sheet metal manufacturer, we are uniquely positioned to offer a seamless transition from low-volume prototype to mass production fulfillment as soon as your concept is ready for market.

How It Works

Sheet Metal Prototyping Rapid Quote

Designed to spec and on your desk in days, not weeks.

1. Submit a Quote Request

We’ll respond within 24 hours or less.

2. Upload Your Drawings

Using our state-of-the-art system.

3. Receive Your Prototype

Delivered to your doorstep in days.

4. Win the Race to Market

Outperform your competitors.

Quotes Within Hours

Delivery Within Days

Prototype to Production

Rapid Sheet Metal Prototyping

By committing to quote each order in 24 hours or less and delivering the highest quality prototypes to your desk in days, we solve an aching problem for our innovator clients who need their mock-up now and need it done right. Our in-house engineer-operators are skilled mechanics who personally oversee every step of your project to proactively avoid untimely mistakes before they happen.

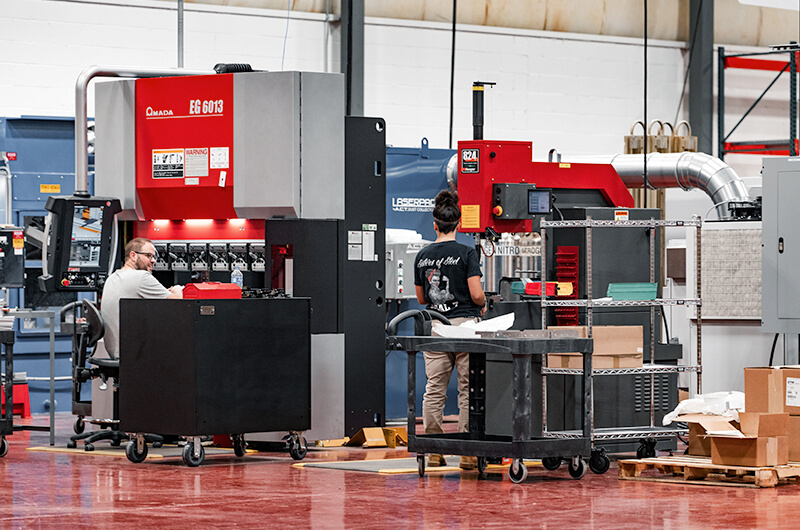

Using state-of-the-art manufacturing technology and a streamlined processes, our crew takes great pride in their work in order to produce top quality prototypes and ensure their reliable, on-time delivery. Once your prototype has been developed, we’ll help you take it to market with our small- and large-scale manufacturing capabilities.

What's your next big idea?

Upload your drawings and get a custom quote in a few hours.

F.A.Q.

Our favorite question is, “How can we help?” Below, we have answered some of the most common inquiries that we receive, but if you are looking for information not provided here, please get in touch, and someone from our crew will respond ASAP.

What is the difference between GTR Manufacturing and GTR ProtoPlus?

To fabricate more precision sheet metal prototypes and provide dedicated floor space to our electromechanical assembly department, we founded our sister company GTR ProtoPlus in 2021.

Besides being housed in two different locations and the types of products produced on the floor space of each, GTR Manufacturing is GTR ProtoPlus. And because of this, you can expect the same quality, service, and capability that has carried GTR’s reputation for the past 5 generations.

How fast can I get a quote?

Once we receive your files, a quote will be submitted back to you within 24 hours. Standard fabrication lead time on flat panels without finish is 5 business days or less and on non-complex geometric parts without finish is 7-10 business days. Standard finishes add approximately 3-5 days depending on type of finish. Our lead time clock starts ticking 24 hours after receipt of order and is calculated as business days (5 days a week, not including weekends). The number of days given represents our ship date and not dock date.

What files can you receive?

We can quote from STEP, SLDPRT, DXF and Native PDF files. We will manufacture from model files.

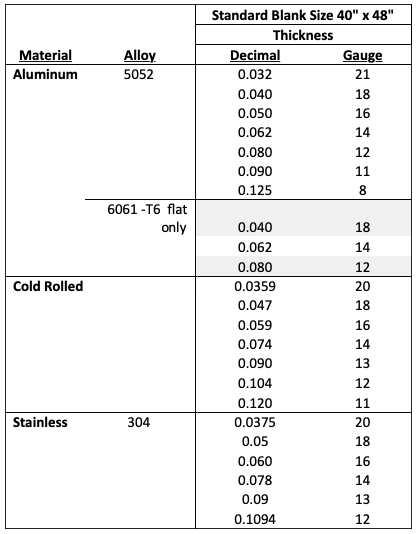

What are your standard materials?

Other materials can be processed, but it may affect normal lead times. Send us your request for quick review.

How do my parts get shipped?

We will gladly process shipments under your preferred logistic organization using your account number or we will provide PrePay and Ship using our UPS account.

What’s the maximum length part you can form?

Our EG6013 67 ton Amada press brakes have a max bend 48″ and max stroke of 5.9″ height.

Do you offer welding?

Yes, we have TIG welding capabilities along with spot welding.

What defines a non-complex geometry part?

Generally speaking, this would be parts with no compound angles, 12 bends or less, assemblies of 5 or less, no machined features, and fit on our standard 40″ x 48″ size blanks. Simply email us your file(s) for a quick evaluation.

Can you handle larger volume order quantities?

Yes, if speed is in need, we can process low-volume production orders. For larger quantities, we seamlessly migrate parts over to our in-house manufacturing team for full-scale production.

What kind of finishes do you offer?

Powder coat, paint, silk-screening, chromate (clear RoHS and yellow), zinc plating, anodize (clear/ black), passivate, and electro-polish.

What are your payment terms?

We offer highly-secured, 3rd party credit card payments. Net 30 terms can be offered to existing customers or with new customers pending credit approval.

“We provide innovators with the highest quality precision sheet metal prototypes and do so at a level of speed, craftsmanship, and service that exceeds all standards and expectations.”

Our Promise

We haven’t built a semi-centennial (50-year-old) business by just making parts alone; our success is equally measured by the trust our clients continually place in us, generation after generation.

Leading the industry with the widest range of world-class precision sheet metal fabrication capabilities under one roof is only one of the many benefits of choosing GTR Manufacturing for your next sheet metal prototyping project.

One Crew

The Industry’s Only Single-source Sheet Metal Manufacturer

Manage one vendor, write one P.O., and hold only one party accountable to your project’s timeline. Only thing left is to decide what to do with all that extra free time.

One-Stop Pit Stop

End-to-end Services, Limitless Capabilities

We’ve got the widest range of world-class precision sheet metal fabrication services under one roof. Got a need for speed? Having autonomy over the entire production process means you get the best of both shorter lead times and uncompromising quality.

One Leader

Setting the Pace Since 1973

Leading the industry for 50 years, we have earned an equal-parts reputation for time-tested reliability and forward-thinking ingenuity. We’re meticulous engineers and expert craftsmen with a set of unmatched tools and experiences under our belt.

Testimonials

From Our Clients

Work with GTR and discover how 50 years of customer service can energize your team, expedite your projects, and exceed your expectations.