Chromate conversion coating, Alodine®, yellow Bonderite®, Iridite®, chem film, “chromating,” and chromate treatment all indicate the same thing–and that “thing” is the passivation of aluminum, cadmium, copper, magnesium, steel, tin alloys, and zinc.

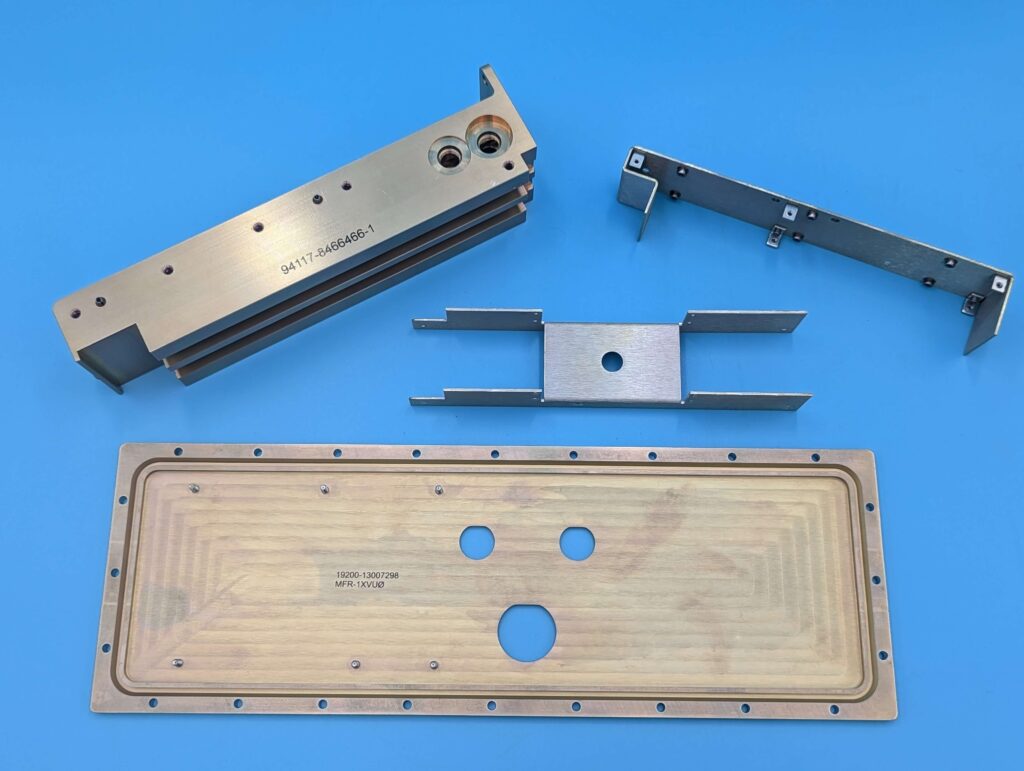

Here at GTR, we most commonly apply chromate conversion coatings to aluminum alloy parts. But chromate coating can look very different from part to part, depending on the purity of the alloy and its surface roughness.

Let’s explore the many different results that are possible with chromate treatment and clear up the most common misunderstandings about this useful process.

What Is Chromate Conversion Coating, Anyway?

Chromate treatment is a chemical conversion coating that we apply to your part’s metal surface. The treatment enhances a part’s electroconductive resistance and corrosion resistance thanks to a chemical reaction between the base material and the chromic-acid-bearing compound.

Unlike plating, which is merely a surface coating, chromating creates a protective film that bonds to the base metal both physically and chemically.

What Will Your Chromate Treated Parts Look Like?

When chromating white or gray metals, the most common cosmetic result is a uniquely iridescent, greenish-yellow color. But the appearance of a chromate-treated part can vary among different alloys.

If we apply identical pretreatments and chromate treatments to 10 different alloys, we’ll see 10 different tones of the chemical film—and the wildest color shifts are found in cast aluminum alloys.

Depending on the type of metal and the composition of your chromate coating, your parts could appear with tones ranging from clear to stark yellow to dark brown.

Military Grade Chromate: Two Terms, One Process

For the majority of parts made here in our sheet metal shop, we apply chromate to these interchangeable military standards:

-

MIL-C-5541

-

MIL-DTL-5541

The two standards are identical yet often cause confusion for customers who request the older terminology—MIL-C-5541—yet see “MIL-DTL-5541” on their purchase order. If this has happened to you, don’t worry! You have received parts that meet your requested standards.

RoHS Compliant Chromate: Clear = Compliant

When parts must be RoHS compliant, their chromate coating will always be clear. It is not possible to deliver a yellow-toned coating that is also RoHS compliant.

Many customers have legacy parts that were yellow chromated in the past. Now, however, the same parts will need to be clear chromated if they must be RoHS compliant.

If you receive your parts and worry that they’re uncoated because they lack the expected yellow tone, rest assured that they have been chromated with the appropriate clear, RoHS-compliant chemical compound.

Weird but True: Yellow Chromate Isn’t Always Yellow

Despite its name, yellow chromate can vary in color from light yellow to golden brown. Yellow chromating is an acid process that leaves subtle etch marks in the part, and the final color cast can vary from lot to lot.

If you’re accustomed to receiving pale yellow parts, and then you receive parts that are nearly brown, you may be concerned that the wrong treatment was applied—or that it was applied too thinly.

It’s important to note that chromate isn’t a coating like plating or painting. Chromate-coated parts undergo a chemical process that causes the color change. And this color is largely dependent on the composition of the underlying material.

Chromate Is Commercial, Not Cosmetic

Chromate is a commercial process for commercial applications, but many people request chromating in search of an ornamental finish.

Chromating is not designed for cosmetic purposes, however. If you’re seeking a specific cosmetic result for your parts, give us a call. We’ll help you select the correct finish for your parts.

Which Chromate Is the Right Chromate for Your Parts?

We’re happy to help you identify the ideal chromate treatment for your part. All you have to do is ask!

If RoHS compliance is required, your parts will need a clear Class 2 chromate. Otherwise, you can select from clear Class 1A or yellow Class 3 chromate.

Class 1A is primarily selected as a primer to enhance paint adhesion and electroconductivity, whereas Class 3 is specified for corrosion resistance.

Your Cheat Sheet for Chromate Callouts

This quick-look list can help you determine which chromate treatment to specify when placing an order with the GTR Manufacturing sheet metal shop:

MIL-C-5541 and MIL-DTL-5541: Type 1, Class 1A or 3

-

MIL-C and MIL-DTL Type 1 chromates are never RoHS compliant

-

Type 1, Class 1A is always yellow

-

Type 1, Class 3 can be either yellow or clear; please specify your color preference

MIL-DTL-5541: Type 2, Class 1A or 3

-

MIL-DTL Type 2 chromates are always RoHS compliant

-

Type 2, Class 1A is always clear and RoHS compliant

-

Type 2 Class 3 is always clear and RoHS compliant

Choose GTR Manufacturing for Chromate Conversion Coating

When you need precision metal fabrication and chromate conversion coating, GTR is your go-to sheet metal shop for quality, cost, and know-how.