Sheet Metal Fabrication

Sheet Metal Shearing

Quick, efficient precision sheet metal shearing. Cost-effective, low-waste method to cut sheets or blanks to a custom size.

Quick • Efficient • Low-Waste

Rapid, Precise Sheet Metal Shearing

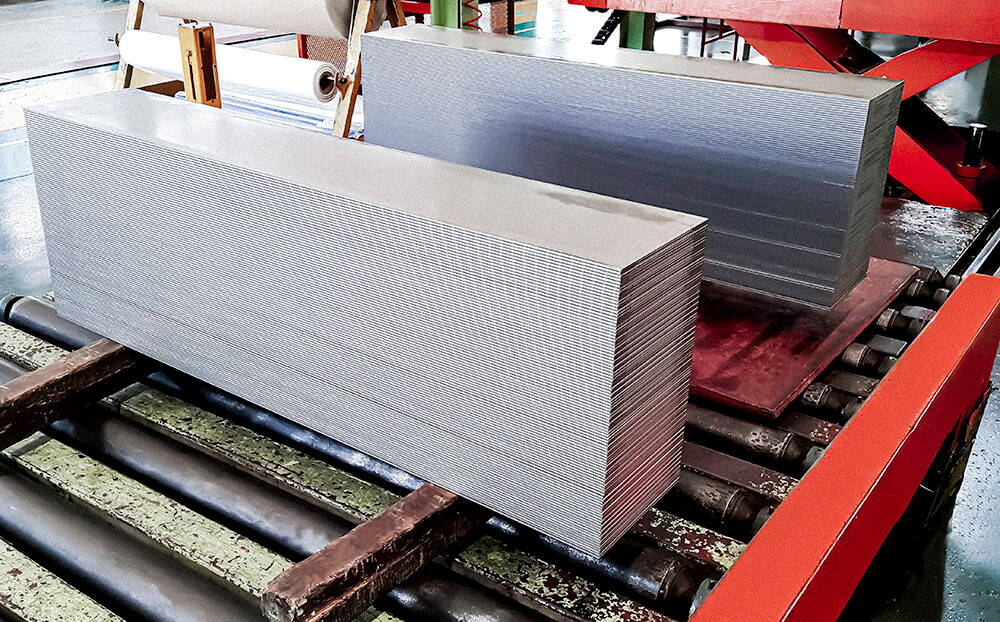

To produce precision sheet metal, shearing is essential to creating high-quality parts and products. Sheet metal comes in many sizes (36″-60″ wide x 96″-144″ long). These sheets need to be cut into smaller pieces (blanks) depending on the size of the produced parts. Our shearing process involves securing a piece of sheet metal between a shearing machine’s top and bottom blades. As the top blade slices through the sheet metal, the material is also pressed onto a lower blade. Excess material is cleanly cut away from the metal part, creating a smooth and highly functional finished piece.

Finally, a highly experienced team of GTR Manufacturing technicians cut the material into blanks or prepare it to be punched or laser cut by our world-class equipment. Since high-quality sheet metal shearing is part of our end-to-end precision sheet metal fabrication capabilities, our customers never face unexpected costs or delays.

Sheet Metal Shearing Features

Sheet Metal Shearing Features

Shearing Machinery Capabilities

GTR Manufacturing’s machinery is capable of the following to achieve the perfect cut:

- Machinery: Amada M-3045 (10′)

- Sheet metal dimensions: Up to 60″ wide and 144″ long

- Sheet metal depth: Up to 4.5 mm

- Tensile strength: 45 kg/sq mm

- Stroke speed: 60 SPM

Benefits of GTR’s Shearing Service

GTR Manufacturing presents a convenient sheet metal shearing solution to our customers:

- Low-waste (no chips)

- Performed in-house at room temperature

- Cost-effective

- All materials evaluated, handled, and processed by tenured machine operators

Engineering & Design Support

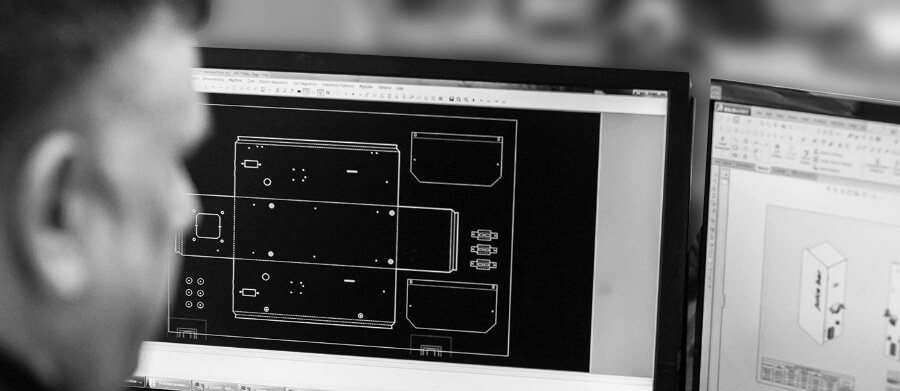

GTR Manufacturing’s experienced engineering department can provide concepts, design changes, product enhancements, and reverse engineering. We will work with your team to deliver your parts at competitive costs.

Our sales, management, and engineering teams have experience in a wide range of industries and understand their changing needs. We work in close partnership with our clients in developing and refining product designs and production process planning to simplify manufacturing and create cost savings for your end product.

We have the capability to import and unfold your 3D models ( .dwg, .step, .iges, .sldasm, .ldprt, .dxf) built in Solid Works, Pro/E, and other modeling software. The model is unfolded and downloaded directly into the CAM process, reducing errors and assisting in short lead times for your sheet metal parts.

JIT / KANBAN

By using the Just-In-Time (JIT) inventory strategy, GTR Manufacturing schedules production to meet your ordering needs. We reduce costs by carrying less idle inventory, resulting in a quality product that is delivered on time at a lower price.

We pair JIT with the Kanban technique to manage our highly-efficient development process. We establish minimum and maximum quantities, fulfilling customer needs on a pull system. This method empowers us to reduce inventory for customers and suppliers and uses lean production practices. In addition, we have full insight into your pipeline through an online portal, ensuring it’s always full.

Is GTR’s Sheet Metal Shearing Service Right For Your Next Project?

With 50+ years of experience assisting customers with diverse fabrication projects, from small and simple to large and complex, GTR creates sheared strips, blanks, or planks in a variety of materials and thicknesses, depending on the unique needs of each project.

When it comes to products of a larger size, we’ve found a smarter approach to the shearing step. We order pre-cut material in blanks to eliminate the need for the shearing process entirely. This expedites the timeline of our customers’ projects, allowing us to get your order out in record time.

Our end-to-end precision sheet metal fabrication capabilities speed up project timelines by lowering the risk associated with relying on external supply chains and allow us to have complete oversight and control over the entire production process—ensuring uncompromising quality.

Our Promise

We haven’t built a semi-centennial (50-year-old) business by just making parts alone; our success is equally measured by the trust our clients continually place in us generation after generation.

One Crew

The Industry's Only Single-source Sheet Metal Manufacturer

Manage one vendor, write one P.O., and hold only one party accountable to your project's timeline. Only thing left is to decide what to do with all that extra free time.

One-Stop Pit Stop

End-to-end Services, Limitless Capabilities

We've got the widest range of world-class precision sheet metal fabrication services under one roof. Got a need for speed? Having autonomy over the entire production process means you get the best of both shorter lead times and uncompromising quality.

One Leader

Setting the Pace Since 1973

Leading the industry for 50 years, we have earned an equal-parts reputation for time-tested reliability and forward-thinking ingenuity. We're meticulous engineers and expert craftsmen with a set of unmatched tools and experiences under our belt.

GTR Answers the Call for Excellence

We understand that our clients build innovative products that are used to save lives, withstand extreme conditions, or perform highly specialized functions. We pride ourselves on doing everything right to deliver on time the first time. We honor our critical role in your project’s overall success and promise to do our part to help you reach the finish line on time.

Quality • Reliability • Capability