Metal Finishing

Powder Coated Sheet Metal

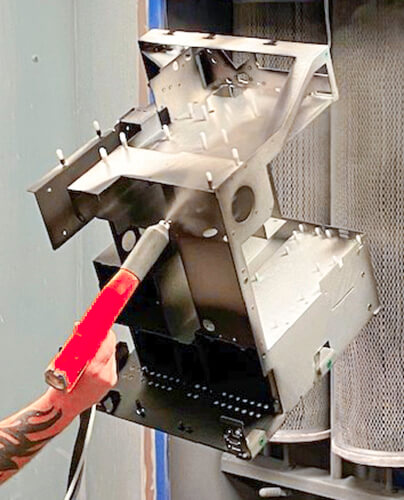

Custom powder coated sheet metal offered in-house. Fast, long-lasting, and environmentally-conscious alternative to epoxy-based paint.

In-House Powder Coated Sheet Metal

GTR Manufacturing offers full powder coated sheet metal as part of our in-house metal finishing capabilities. Powder coating relies on electrostatic application—as opposed to the physical application of liquid paint—which makes it a faster, more durable, and more environmentally friendly method of product finishing.

In addition to precision sheet metal fabrication services, we maintain and operate an on-site facility dedicated solely to metal finishing. Our capabilities include five separate painting booths, with a total area of 672 sq. feet, and two ovens, with a combined area of 192 sq. feet, allowing us to handle large jobs. Our team members are also exceptionally skilled in chip-matching and can maintain texture consistency while working with any type of material.

Unlike other fabricators, our one-stop-shop approach avoids subcontracting processes, extra handling costs, and time-consuming transfers.

Powder Coating Features

Powder Coating Features

Powder Coating Benefits

In a single-coat application, textures are built directly into the powder formula, resulting in a thicker and more uniform finish without running or sagging.

- Uniform finish

- Chip-resistant

- Rust-resistant

- Reduced carbon footprint

- Faster turn-around time than painting

Our Powder Coating Process

Powder coating is an alternative to our epoxy-based painted sheet metal capabilities. Here’s how the process works:

- Along with the selected pigment color, very fine and dry resin particles are applied to the product with an electrostatically charged spray gun.

- The product is then baked in industrial-sized ovens—GTR Manufacturing’s facilities include two of these specialty ovens with a combined square footage of nearly 200 feet, allowing us to handle large production jobs.

- The melted resin fuses with the metal during heating, providing a uniform, thick, and durable finish.

Health & Safety Benefits of Powder Coats

Powder coated sheet metal methods are versatile, as they can be easily applied to objects or metals that have structures or properties that would make them difficult to cover with liquid paint. Powder coating also eliminates the need for using Volatile Organic Compounds (VOCs), which are often found in solvents or organic paints.

The EPA states that VOCs can be harmful pollutants, but the dry materials in powder coating do not include VOCs. As a result, powder-coated products can stand up to a variety of conditions all while leaving a smaller carbon footprint.

Our end-to-end precision sheet metal fabrication capabilities not only speed up project timelines by lowering the risk associated with relying on external supply chains but also allow us to have complete oversight and control over the entire production process — ensuring uncompromising quality.

Is GTR’s Aluminum Powder Coating Service Right For Your Next Project?

- Is your business in need of metal finishing that meets strict industry requirements?

- Have other manufacturers looked at your blueprints and ruled that your systems are “too difficult” or complicated to create?

- Are you looking for a straightforward paint job but are surprised at how long the lead times are?

We are proud to simplify the precision sheet metal manufacturing processes by offering sheet metal finishing under the same roof as our other premium services.

Our end-to-end capabilities speed up project timelines by lowering the risk associated with relying on external supply chains and give us complete oversight and control over the entire production process—ensuring uncompromising quality.

Our Promise

We haven’t built a semi-centennial (50-year-old) business by just making parts alone; our success is equally measured by the trust our clients continually place in us generation after generation.

One Crew

The Industry's Only Single-source Sheet Metal Manufacturer

Manage one vendor, write one P.O., and hold only one party accountable to your project's timeline. Only thing left is to decide what to do with all that extra free time.

One-Stop Pit Stop

End-to-end Services, Limitless Capabilities

We've got the widest range of world-class precision sheet metal fabrication services under one roof. Got a need for speed? Having autonomy over the entire production process means you get the best of both shorter lead times and uncompromising quality.

One Leader

Setting the Pace Since 1973

Leading the industry for 50 years, we have earned an equal-parts reputation for time-tested reliability and forward-thinking ingenuity. We're meticulous engineers and expert craftsmen with a set of unmatched tools and experiences under our belt.

Yeah, we do that, too...

Metal Finishing Capabilities

Chem Film

Powder Coating

Silk Screening

GTR Services

Sheet Metal Prototyping

Precision Sheet Metal Fabrication

CNC Milling & Turning

Metal Finishing

Electromechanical Assembly

Manufacturing Support

About GTR Manufacturing

Meet Our Crew

Metal Fabrication Jobs

Get A Quote

GTR Answers the Call for Excellence

We understand that our clients build innovative products that are used to save lives, withstand extreme conditions, or perform highly specialized functions. We pride ourselves on doing everything right to deliver on time the first time. We honor our critical role in your project’s overall success and promise to do our part to help you reach the finish line on time.

Quality • Reliability • Capability