Sheet Metal Fabrication

Sheet Metal Welding

High-quality, cost-effective sheet metal welding performed on-site by our American Welding Society QC1 certified welding experts.

High-Quality • Superior Craftsmanship

Expert, In-House Sheet Metal Welding

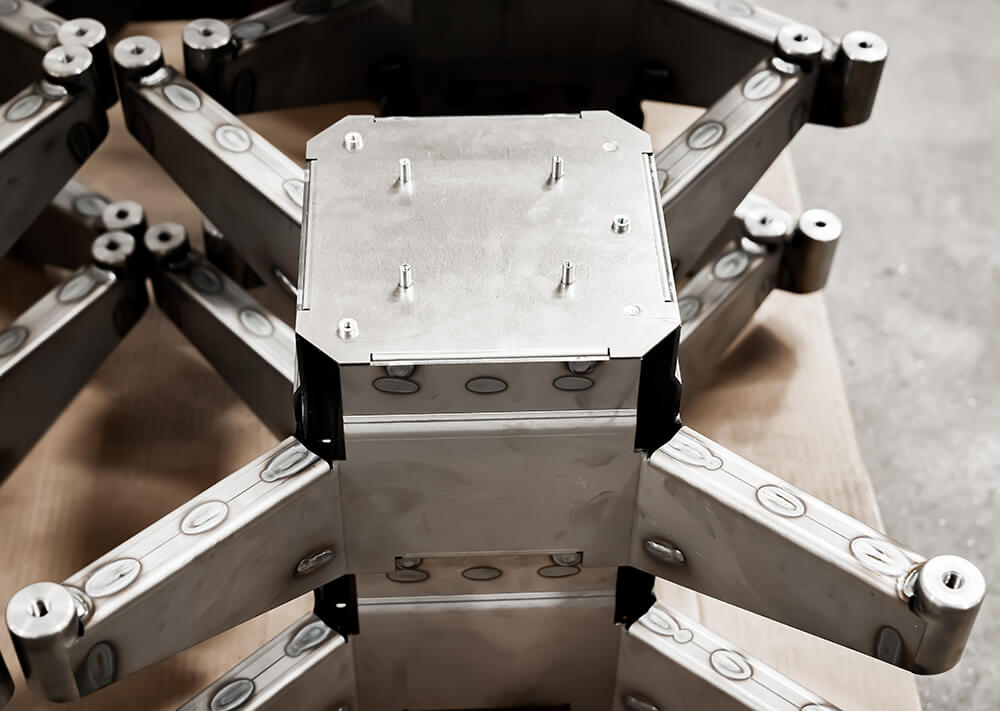

Because we understand how essential welding is to create innovative and high-quality sheet metal parts, we at GTR Manufacturing have a best-in-class welding department. Our manufacturing floor has 13 Miller welding machines in five different models, allowing us to complete jobs on all types of metal and thicknesses, from light gauge aluminum to 3/8″ plate. As part of providing the very best to our clients, 5 of these welding machines are Dynasty 400s, and three are Dynasty 350s. These machines are state-of-the-art AC and DC inverters, which allow our craftsmen to precisely control heat input and arc stability like never before. In addition, Dynasty welding technology allows for reduced warpage, increased travel speeds, and maximal puddle control.

Our team, made up of skilled craftspeople, highly-qualified welders certified to AWS 3.2, and an in-house Certified Welding Inspector (AWS QC1), can complete various complex and specified processes to meet the exact needs of your project. Not sure exactly which welding process would work best for your order? Don’t hesitate to reach out to one of our industry experts. Simply put, there’s no need to go anywhere else for an incredible welding job.

Welding, a process of fusing two pieces of metal together through heat application, has been the backbone of metal fabrication since industrial times. Today’s modern welding industry is extremely versatile and can be essential to the precision sheet metal fabrication process. GTR Manufacturing brings our nearly fifty years of expertise to the following types of welding services: MIG welding, TIG welding, and spot welding.

Sheet Metal Welding Features

Sheet Metal Welding Features

GTR’s Sheet Metal Welding Techniques

Our expert craftspeople have the capability and expertise to perform some of the most skilled welding techniques:

- MIG – The Metal Inert Gas technique, also known as gas metal arc welding (GMAW), uses an auto-feeding solid wire electrode to fuse two base materials together, and shielding gas is fed alongside the electrode to protect the finished product from airborne contaminants. MIG welding is ideal for heavy-duty projects requiring flexibility and high deposition rates. It is a lower-cost welding option.

- TIG – Like MIG, Tungsten Inert Gas, or gas tungsten arc welding (GTAW), makes use of shielding gas but instead utilizes a consumable tungsten electrode and a manually-fed welding rod. This technique requires a high level of skill and mastery to be successful, but it produces extremely accurate and precise results with a level of aesthetic quality that cannot be beaten, making it ideal for thinner metals and delicate projects.

- Spot Welding – Spot welding, or resistance spot welding, uses both pressure and heat to the desired area, joining two flat surfaces between copper electrodes and avoiding distortion due to heat from conventional MIG or TIG welding. One of the most common forms of welding used in the manufacturing industry, spot welding can be desirable for jobs because spot welding sheet metal is cost-effective and does not consume any materials during the welding process.

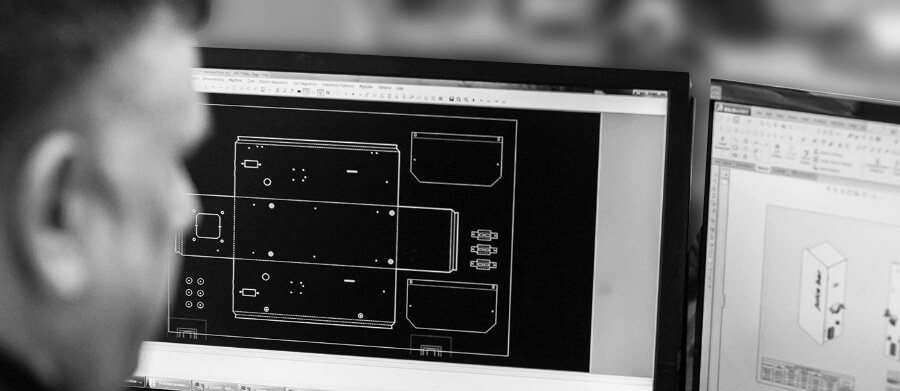

Engineering & Design Support

GTR Manufacturing’s experienced engineering department can provide concepts, design changes, product enhancements, and reverse engineering. We will work with your team to deliver your parts at competitive costs.

Our sales, management, and engineering teams have experience in a wide range of industries and understand the changing needs of all of them. We work in close partnership with our clients in developing and refining product designs and production process planning to simplify manufacturing and create cost savings for your end product.

We have the capability to import and unfold your 3D models ( .dwg, .step, .iges, .sldasm, .ldprt, .dxf) built in Solid Works, Pro/E, and other modeling software. The model is unfolded and downloaded directly into the CAM process, reducing errors and assisting in short lead times for your sheet metal parts.

JIT / KANBAN

By using the Just-In-Time (JIT) inventory strategy, GTR Manufacturing schedules production to meet your ordering needs. We reduce costs by carrying less idle inventory, resulting in a quality product that is delivered on time at a lower price.

We pair JIT with the Kanban technique to manage our highly-efficient development process. We establish minimum and maximum quantities, fulfilling customer needs on a pull system. This method empowers us to reduce inventory for customers and suppliers and uses lean production practices. In addition, we have full insight into your pipeline through an online portal, ensuring it’s always full.

Is GTR’s Sheet Metal Welding Service Right For Your Next Project?

Our team made up of skilled craftspeople, highly-qualified Certified Welders, and an in-house Certified Welding Inspector (AWS QC1), is able to complete a variety of complex and specified processes to meet the exact needs of your project.

Not sure exactly which welding process would work best for your order? Don’t hesitate to reach out to us. GTR Manufacturing’s extensive industry experience and attention to detail allow us to advise customers on their projects’ welding needs confidently.

Our Promise

We haven’t built a semi-centennial (50-year-old) business by just making parts alone; our success is equally measured by the trust our clients continually place in us generation after generation.

One Crew

The Industry's Only Single-source Sheet Metal Manufacturer

Manage one vendor, write one P.O., and hold only one party accountable to your project's timeline. Only thing left is to decide what to do with all that extra free time.

One-Stop Pit Stop

End-to-end Services, Limitless Capabilities

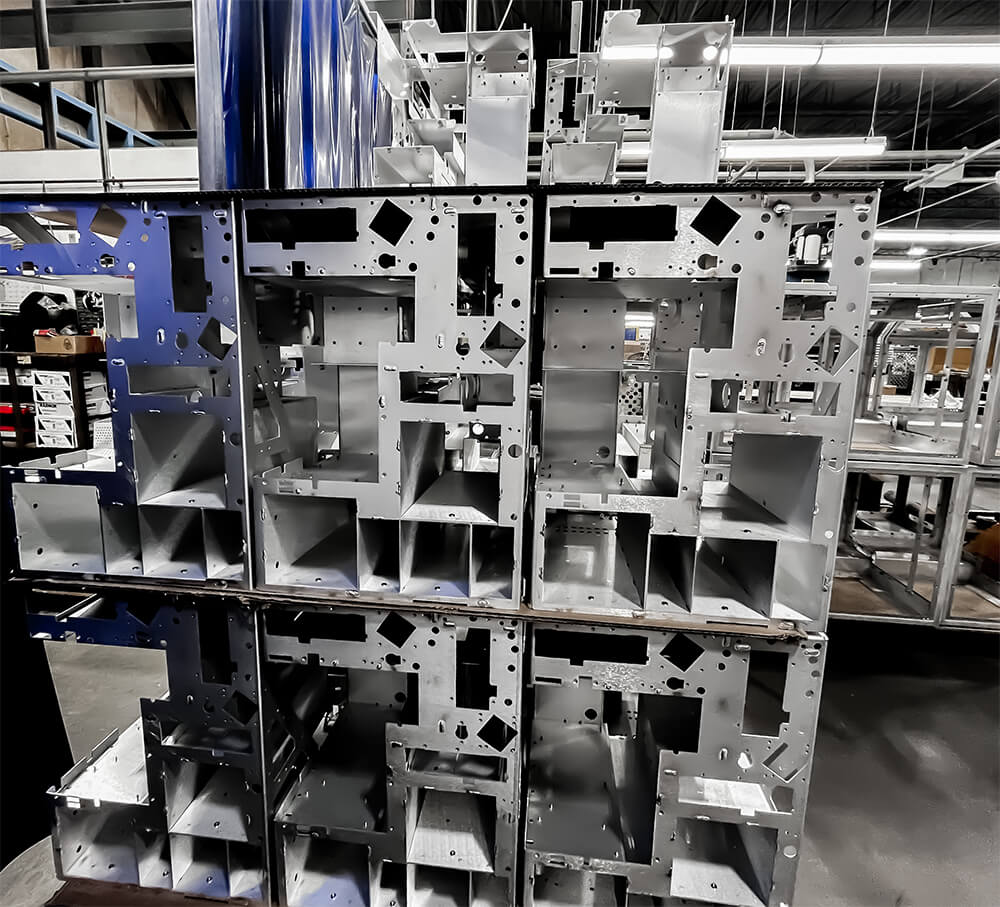

We've got the widest range of world-class precision sheet metal fabrication services under one roof. Got a need for speed? Having autonomy over the entire production process means you get the best of both shorter lead times and uncompromising quality.

One Leader

Setting the Pace Since 1973

Leading the industry for 50 years, we have earned an equal-parts reputation for time-tested reliability and forward-thinking ingenuity. We're meticulous engineers and expert craftsmen with a set of unmatched tools and experiences under our belt.

Yeah, we do that, too...

Metal Fabrication Capabilities

Forming

Grinding & Sanding

Laser Cutting

Laser Punch Combo

Punching

Shearing

Spot Welding

Welding

GTR Services

Sheet Metal Prototyping

Precision Sheet Metal Fabrication

CNC Milling & Turning

Metal Finishing

Electromechanical Assembly

Manufacturing Support

About GTR Manufacturing

Meet Our Crew

Metal Fabrication Jobs

Get A Quote

GTR Answers the Call for Excellence

We understand that our clients build innovative products that are used to save lives, withstand extreme conditions, or perform highly specialized functions. We pride ourselves on doing everything right to deliver on time the first time. We honor our critical role in your project’s overall success and promise to do our part to help you reach the finish line on time.

Quality • Reliability • Capability